Ideal nutrition for plants

The right CO2 concentration in the water is of great importance for the aquarium plants. Carbon dioxide is the main nutrient for plants and promotes their growth. Plants use the CO2 for the photosynthesis and thus supply the water with essential oxygen. They prevent algae growth, remove pollutants, provide hiding places and reduce pathogens.

Economical and direct

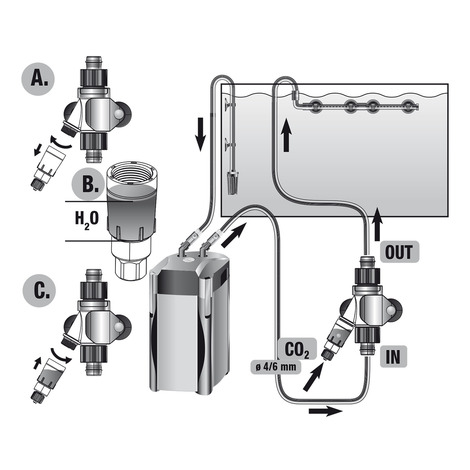

This practical CO2 direct diffuser saves a diffuser in the aquarium, a bubble counter and a check valve. It even saves 20 % CO2 thanks to its ingenious functioning. All that is needed is an external filter with a suitable hose connection.

Easy to install

In order to ensure that the CO2 gas passes as far along the inside of the hose as possible, the direct diffuser needs to be integrated into the hose as close as possible to the external filter. A vertical mounting position will ensure the best readability of the bubble counter.

JBL PROFLORA Direct

High performance direct diffuser for CO2

PROFLORA CO2 TAIFUN INLINE

- For an economical and direct plant fertilisation: CO2 diffuser for external filters

- Easy to install: connect to hose of external filter

- Exact dosing: integrated bubble counter, no water backflow thanks to backflow stop

- 20 % CO2 saving due to an especially effective diaphragm

- Package contents: 1 ready-for-connection high performance CO2 direct diffuser

You may also be interested in

JBL PROFLORA Direct 12/16

Properties

| Animal species: | Armored catfish, Arowana, Axolotl, Barbels, Bettas, Bichirs/reedfish, Blowfish, Catfish, Cichlids (South America), Clawed frogs, Clawed shrimps, Crayfish, Crustaceans, Danions, Discus, Dwarf crayfish, Dwarf shrimps, Flowerhorn, Gill maggots, Goldfish, Gouramis, Guppy, Juvenile fish, Killifish, Livebearers, Loaches, Mussels, Newts, Panchaxes, Rainbowfish, Snails, Spiny eels, Tetra, Veiltails, blood parrot cichlids, freshwater butterflyfish |

| Animal size: | For all animal sizes |

| Animal age group: | All aquarium fish |

| Volume habitat: | 40 - 300 L |

| Material: | plastic (PC) |

| Colour: | black / white / grey |

Electronic label / illuminant

| Mercury: | No |

| Dimmable: | No |

Technical Data

| capacity from - to: | 40-300l |

| Height: | 140 mm |

| Length: | 80 mm |

| Width: | 52 mm |

JBL PROFLORA Direct 16/22

Properties

| Animal species: | Armored catfish, Arowana, Axolotl, Barbels, Bettas, Bichirs/reedfish, Blowfish, Catfish, Cichlids (South America), Clawed frogs, Clawed shrimps, Crayfish, Crustaceans, Danions, Discus, Dwarf crayfish, Dwarf shrimps, Flowerhorn, Gill maggots, Goldfish, Gouramis, Guppy, Juvenile fish, Killifish, Livebearers, Loaches, Mussels, Newts, Panchaxes, Rainbowfish, Snails, Spiny eels, Tetra, Veiltails, blood parrot cichlids, freshwater butterflyfish |

| Animal size: | For all animal sizes |

| Animal age group: | All aquarium fish |

| Volume habitat: | 160 - 600 L |

| Material: | plastic (PC) |

| Colour: | black / white / grey |

Electronic label / illuminant

| Mercury: | No |

| Dimmable: | No |

Technical Data

| capacity from - to: | 160-600 |

| Height: | 140 mm |

| Length: | 80 mm |

| Width: | 52 mm |

JBL PROFLORA Direct 19/25

Properties

| Animal species: | Armored catfish, Arowana, Axolotl, Barbels, Bettas, Bichirs/reedfish, Blowfish, Catfish, Cichlids (South America), Clawed frogs, Clawed shrimps, Crayfish, Crustaceans, Danions, Discus, Dwarf crayfish, Dwarf shrimps, Flowerhorn, Gill maggots, Goldfish, Gouramis, Guppy, Juvenile fish, Killifish, Livebearers, Loaches, Mussels, Newts, Panchaxes, Rainbowfish, Snails, Spiny eels, Tetra, Veiltails, blood parrot cichlids, freshwater butterflyfish |

| Animal size: | For all animal sizes |

| Animal age group: | All aquarium fish |

| Volume habitat: | 200 - 800 L |

| Material: | plastic (PC) |

| Colour: | black / white / grey |

Electronic label / illuminant

| Mercury: | No |

| Dimmable: | No |

Technical Data

| capacity from - to: | 200-800 |

| Height: | 140 mm |

| Length: | 80 mm |

| Width: | 52 mm |

You don't have to worry. The gas exchange at the water surface with our breathing air, which also contains CO2, is very important for the aquarium environment. The diffuser should therefore move the water surface and thus promote gas exchange and prevent a build-up of surface scum. Most of the CO2 is already dissolved in the water column coming from the external filter. The membrane of the JBL PROFLORA Direct atomises the CO2 into fine bubbles which are carried along with the flow and dissolve in the hose. Unlike reactors, the bubbles here are very fine and light. The part that is not yet dissolved then swirls around in the aquarium as it drifts in and continues to dissolve. It is normal and unavoidable that some of the bubbles "pop out" at the surface. Nevertheless, this method is very effective.

True to the motto, better safe than sorry, some aquarists install several check valves in the same circuit. For example, if you use the JBL PROFLORA direct inline diffuser or the JBL PROFLORA CO2 Count Safe bubble counter, you already have an integrated check valve. If you also use a separate check valve (JBL PROFLORA SafeStop), there may be problems with the opening of the check valves. This effect can be observed if, after the night switch-off or interruption of the supply with the controller, the addition does not restart automatically. Please note that, depending on the working pressure and the number of bubbles, a few minutes may pass between the start of the supply and the visible entry of CO2 into the aquarium.

Each spring in a check valve needs a certain pressure to be opened. Several springs can therefore interfere with each other and, depending on the distance between the two check valves, reduce the pressure at the spring to such an extent that it remains closed. Therefore, please always use only one check valve for your CO2 installation.

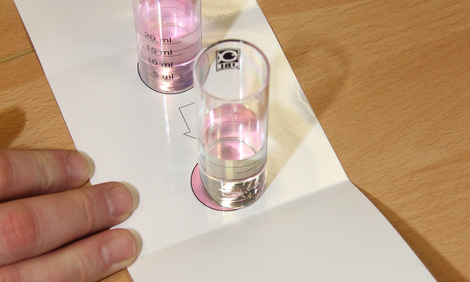

The bubble counter of the JBL PROFLORA® Direct diffuser is filled with water and screwed to the body © as shown in figure B of the instructions for use. During operation, water level fluctuations may occur in the bubble counter, depending on the amount of CO2 added. A large number of bubbles with high working pressure can displace the water from the chamber. Once the addition stops, water will enter the chamber again with a time delay. If the membrane is dirty, the chamber will remain empty. Cleaning the membrane is necessary, as described in the other FAQs.

To receive a consistent bubble pattern with fine micro bubbles, the modern ceramic PE hybrid membrane needs to be soaked in water before putting it into operation. If this is not done, large bubbles will occur.

We recommend a working pressure of 1.0 – 1.5 bar.

In order to enable the modern ceramic PE hybrid membrane to build consistent micro bubbles and to ensure an effective

CO2 spread in the water, it needs to be soaked in water for approx. 24 hours before being put into operation. Do not, therefore, switch on the CO2 supply after installation until the period of time mentioned has passed. Alternatively you can put the membrane into a bowl of water. Without this soaking the pores will not have enough water and will let large bubbles pass with an uneven distribution.

At first the air hoses and special CO2 hoses can easily be pushed on the connection piece. The hoses harden more and more as the months go on and can only be removed from the connection piece using great force. If you pull the hose hard it will only strain the connection, which could, in the worst case, even break off. Instead cut the hoses you want to remove laterally at the ends and carefully remove them. For this it’s always advisable to install hoses with some reserve in its hose length.

The size of the bubbles is essential to providing compatibility. That’s why you cannot compare the number of bubbles in the ProFlora direct with the old method of determining the bubbles (e.g. with the ProFlora Count (safe) or other bubble counters). Depending on the method used, the bubble size can differ by up to 300 %. That’s why it’s important to use the same bubble counter when comparing both systems in order to determine the conversion factor “bubble number in the old bubble counter” to “bubble number in the ProFlora direct”. Since there is no standard CO2 bubble size, it is otherwise difficult to determine the true conversion rate.

We wouldn’t recommend installing the JBL ProFlora Direct in a bio-CO2 system. The working pressure is not big enough to achieve an even addition of the CO2. Moreover, there is a danger that the pressure will not be able to escape through the integrated check valve, and this can lead to damage in the reaction vessel, if it isn’t able to withstand the pressure.

The retaining spring in the check valve fits very tightly and ensures that no water can return. Therefore the air pressure of a diaphragm pump or our breath is not strong enough to open the spring. The valve can be opened by the pressure of the ProFlora bioCO2 systems and also the m and u series. Check valves used in air systems have a smaller counter-pressure and are also part of the JBL range.

Please wait until sufficient pressure has built up in the CO2 hose. Alternatively you can sharply increase the CO2 supply for a short time.

In this CO2 diffuser the CO2 gets pressed through a fine diaphragm. Depending on the counter-pressure, this sometimes causes a slight chirping sound. If the sound intensifies during operation this indicates a soiling of the diaphragm or change in the operating pressure. Please clean the diaphragm and reduce the operating pressure, if required.

If there is no water in the bubble counter after the installation, just wait a few hours before switching on the CO2 supply. The water jet of the filter will then cause water to enter it. Alternatively while installing it, you can fill the chambers of the bubble counter with water.

Reviews

0 Reviews

9 more reviews in other languages

9 Reviews in other languages

Idealer Diffusor für alle, die wenig Platz im Aquarium haben oder so wenig Technik wie möglich innerhalb des Aquariums / Aquascapes haben wollen (wegen der Optik).

Ich verwende seit ca. 2 Jahren den Inline Diffusor in Kombination mit dem e902 Filter und e300 Heizer an meinem 125l Becken und bin sehr begeistert.

-->Gebrauchsfertige Auslieferung.

-->Man muss lediglich die Membran 24 Wässern

-->Seltene Reinigung notwendig

-->Nicht hörbar

-->Gute Ersatzteilversorgung

-->Integrierter Blasenzähler

Viele Grüße

aquaristik_4_life

(Schaut gerne auf meiner Instagram Seite vorbei :-))

Man liest sehr viel über Probleme mit dem Gerät. Ich kann das nicht bestätigen. Ich habe festgestellt daß die Membran manchmal einen leichten Grat aufweist. Die Auflagefläche zur Dichtung könnte also nicht immer ganz optimal sein. Mit etwas Sandpapier kann man das beheben. Dann ist es auch wichtig den Diffusor !vorsichtig! bis zum Anschlag zuzuschrauben. Ich habe die Gewinde und Dichtungen auch noch mit geeignetem Mittel geschmiert. Alles ist gut. Super Gerät. Dann noch was zu den Bläschen. Es kommen immer welche raus. Das liegt daran das der Osmotische Druck in Beide Richtungen wirkt. Aus der CO2 Blase diffundiert Gas ins Wasser, zugleich Kommt gelöstes Gas vom Wasser in die Blase. Das nennt man "Falschgas". Diese Bläschen erkennt man daran das sie nicht mehr kleiner werden. Eventuelle Undichtigkeiten vom Schlauchanschluss kann man mit Kabelbindern verhindern.

deseando que llegue para cambiarlo por mi reactor de dentro del acuario y asi tenerlo mas disimulado

Sehr empfehlenswert, wenn man auf die Optik von einem Diffusor im Becken verzichten will/kann. Alles ist dicht. Kein Wasser oder CO2 tritt aus. Durch den Einsatz von dem Inlinediffusor spart man etwas Gas, da es länger im aus strömenden Wasser gelöst wird. Durch den Einbau im Unterschrank verschwindet wieder ein künstliches Bauteil aus dem Sichtbereich im Becken.

Absolut klasse das es dieses Produkt gibt. Arbeitet auch an Co2-Anlagen mit weniger Druck. Ich bin sehr zufrieden. Wartungsarm und versteckt im Unterschrank.

Klasse Produkt zum Co2 zuführen

Endlich keine Bläschen mehr im Aquarium, super zu installieren und einfache Handhabung.

Toller Inline Diffusor!

Bin begeistert, bisher funktionieren alle drei Diffusoren, die ich aktuell betriebe, einwandfrei.

Ganz Klarer Vorteil zu anderen Diffusoren: keine Technik im Becken.

Perfekt für alle Becken die mit einem Außenfilter betrieben werden!

Jeder, der sichtbare Technik vermeiden möchte, sollte bei diesem Produkt zuschlagen. Der Inlinediffusor löst das CO2 zu fast 100% auf, sodass im Becken nichts mehr zu sehen ist. Geschweige denn ein extra Diffusor. Die Verarbeitung ist gut, die Membrane tauschbar. Was möchte man mehr. Die Montage ist dank der Anleitung ebenfalls ein Kinderspiel.